Why is CNC lathe service important?

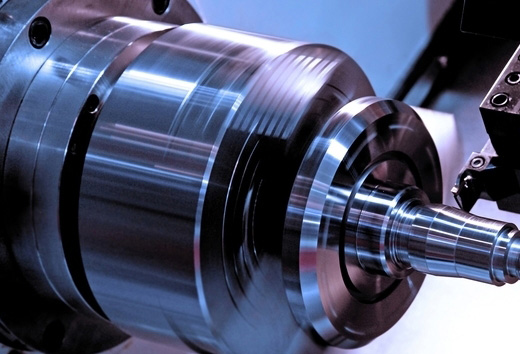

CNC lathe service is a machining procedure that depends on a PC to manufacture an exact rendering of an advanced outline. CNC lathe service have supplanted a significant number of the more established style creation lathes. CNC innovation, which has quickly progressed as of late, is making it simpler than any time in recent memory to make and create dependable segments, items, and tools out of sheets of metals, plastics, and even woods. The present-day lathe machine is intended to utilize propelled adaptations of carbide tooling and forms. In any case, it is as yet feasible for a section or tool way to be structured physically. CNC lathe is only one normal machining process that exploits the ongoing advances in machining innovation.

To get predominant outcomes from CNC lathe service, a coded PC document is transferred to the real CNC machine. It offers various advantages, including expanded creation speed, upgraded generation productivity, more cost-adequacy, and more secure mechanical activities. From that point, the machine naturally creates the parts or segments dependent on the information programming data. Contrasted and human-worked machining forms, CNC machining produces higher quality outcomes in a more cost-and time-viable way. The pieces of the lathe machine joined with accuracy PC writing computer programs are the reasons that completed items are delivered to correct details. Turning is the demonstration of utilizing a lathe—it comprises of utilizing a slicing tool to expel material from a bigger work piece. Deep accuracy is the essential advantage of a lathe machine. Due to modernization and customization, the way of the tool utilized is usually modified utilizing CAD forms.

Today, it's conceivable to expel human mediation from the turning procedure on account of the help of CNC support. CNC lathe machining procedures are performed consequently while being guided by a PC. There are a few different kinds of cnc turning service forms at present accessible. An effective administrator sees a reproduction with respect to the machine's usefulness during the creation stage, the genuine lathing procedure is for all intents and purposes robotized completed item.

.png)

.png)

.png)

.png)

.png)